-

Advanced Temperature Control Systems in Modern PTFE Extruders: Engineering Breakthroughs

Advanced Temperature Control Systems in Modern PTFE Extruders: Engineering Breakthroughs Advanced Temperature Control Systems in Modern PTFE Extruders: Engineering Breakthroughs Introduction: Why ±0.5°C Matters in PTFE Processing “Can a 2°C temperature fluctuation ruin \$500,000 worth of m...Read More -

What Maintenance Is Required for a PTFE RAM Extruder? A 2025 Technical Guide

Introduction: The Critical Role of Maintenance in PTFE Polymer Extrusion “Can proper maintenance double the lifespan of your PTFE RAM extruder? Industry data from Plastics Technology Magazine confirms that 68% of extruder failures stem from inadequate maintenance. This guide reveals systema...Read More -

What Types of Materials Can Be Extruded with a PTFE RAM Extruder?

1、Introduction: Key Applications and Custom PTFE Extrusion Solutions PTFE (Polytetrafluoroethylene) RAM extruders are specialized machines for processing high-performance polymers. If you’re wondering “what materials work with PTFE RAM extruders?”, the answer spans pre-sinterin...Read More -

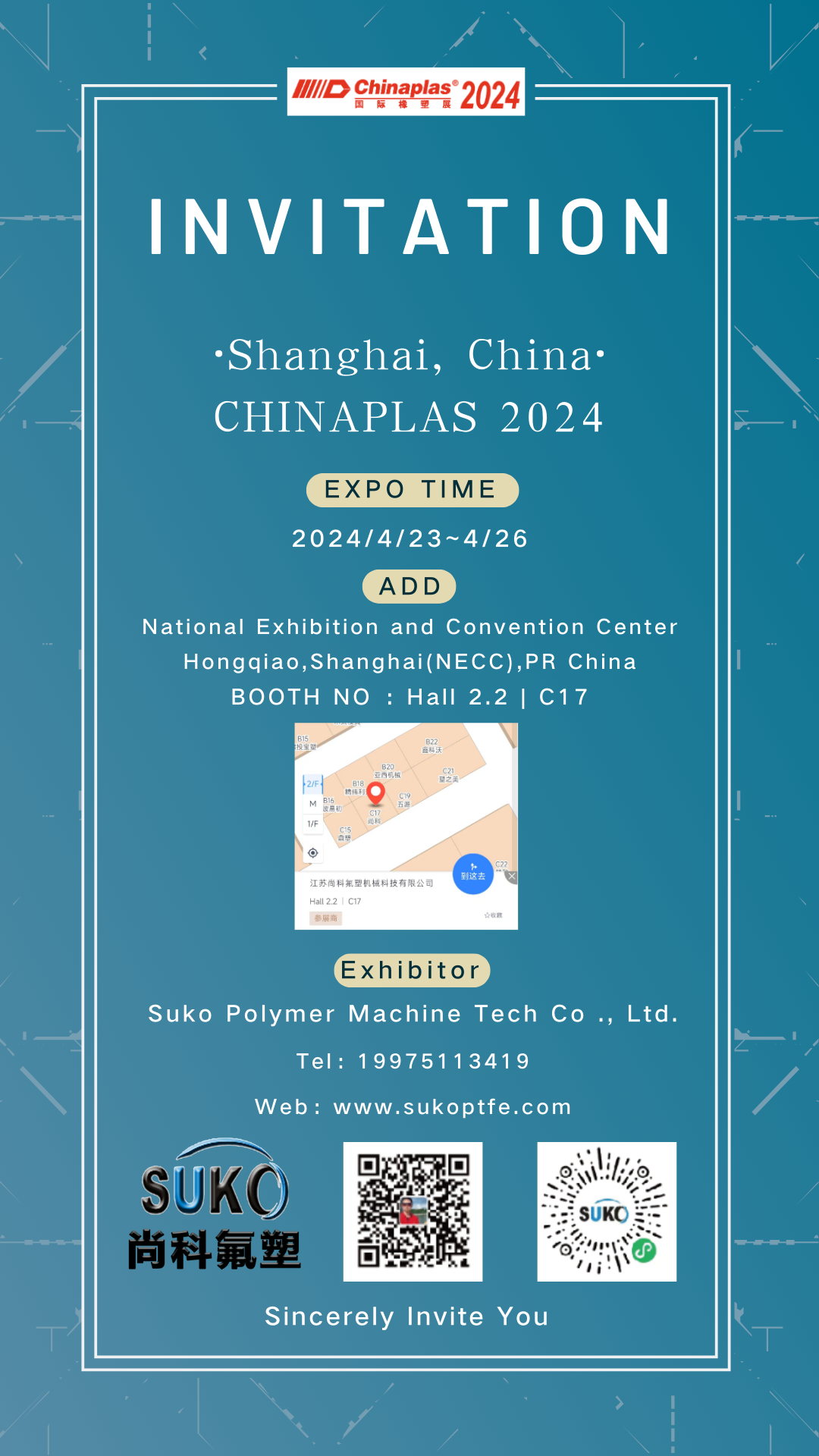

2024 CHINAPLAS | SUKO POLYMER SINCERELY INVITE YOU

Spring is thick, innovation is non-stop. With anticipation and passion, we are participating in the high-profile 2024 CHINAPLAS. The event was held from April 23 to 26 at Shanghai Hongqiao National Convention and Exhibition Center, China, Our booth is located in Hall 2.2, C17 At the exhibition si...Read More -

CHINAPLAS 2024 | Sincerely Invite You

On April 23, 2024, the 36th CHINAPLAS will be grandly launched in Shanghai National Convention and Exhibition Center, as Asia’s leading plastic and rubber exhibition, “CHINAPLAS ” will fully promote the high-end, intelligent and green development of rubber and plastics industry....Read More -

Teflon Ultra-High Temperature Cable PTFE Wire Extruder Production Line Machine

Teflon Ultra-High Temperature Cable PTFE Wire Extruder Production Line Machine is a cable with high temperature resistance, which is often used for electrical connection in high temperature environments such as power generation, metallurgy, and chemical industry. In order to produce such high-qu...Read More